Special Tooling

Table of Contents

Understanding Special Tooling

Special Tooling represents a fundamental component within the manufacturing world that aligns with the intricacies of precision and unique design. It encompasses the bespoke tools, apparatus, and support systems critical for crafting components with exact specifications. At Stanek Tool & Die Inc., we immerse ourselves in the artistry of manufacturing equipment tailored to the individualistic needs of our clients.

Manufacturing industries that pivot on the axis of innovation consistently reach out for Special Tooling. They look for equipment that can’t be found on the shelves of general hardware suppliers. Our team, with their extensive experience and technical expertise, steps up to the challenge by creating these specialized assets with meticulous attention to detail.

The Role of Special Tooling in Manufacturing

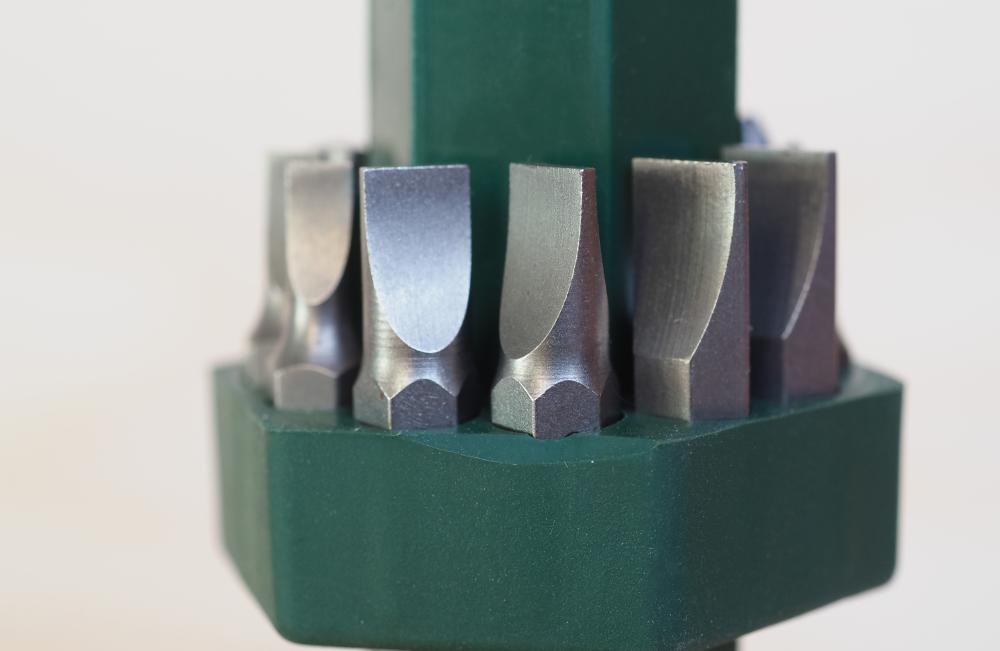

When I think of Special Tooling, what comes to mind is the backbone of custom manufacturing processes. It’s the jigs and fixtures that guide a cutting tool with unyielding precision or the specially designed dies that shape metal with the press of a button. These tools become invaluable when the goal is to produce parts with the highest level of precision.

But why is Special Tooling so indispensable? In my time at Stanek Tool & Die Inc., I’ve watched intricate designs come to life, parts that not only fit perfectly within advanced machinery but also help these machines achieve their monumental tasks. Whether in aerospace or automotive industries, the reliance on these tools is the thread that stitches progress and innovation together.

Designing for Specific Needs

One of the most captivating aspects of Special Tooling is the design process. It’s a symphony of engineering where every note must be in perfect harmony. We often start with raw concepts, turning them into reliable tools that cater to the exact needs of our clients. It’s an orchestration of design software, material selection, and precision engineering.

The design journey begins with a thorough assessment of project requirements. It’s not unusual for our designers to spend hours, sometimes days, conceptualizing before the design crystallizes into its final form. This dedication ensures that each tool we produce is not just a piece of metal but a key enabler of our client’s vision.

Our portfolio boasts designs that have turned industry challenges into standard operations. It’s a testament to the foresight and engineering prowess that my colleagues possess. Custom dies that stamp out futuristic car components, molds that shape cutting-edge medical devices — each project is a narrative of precision and custom craftsmanship.

Technological Advancements in Tooling

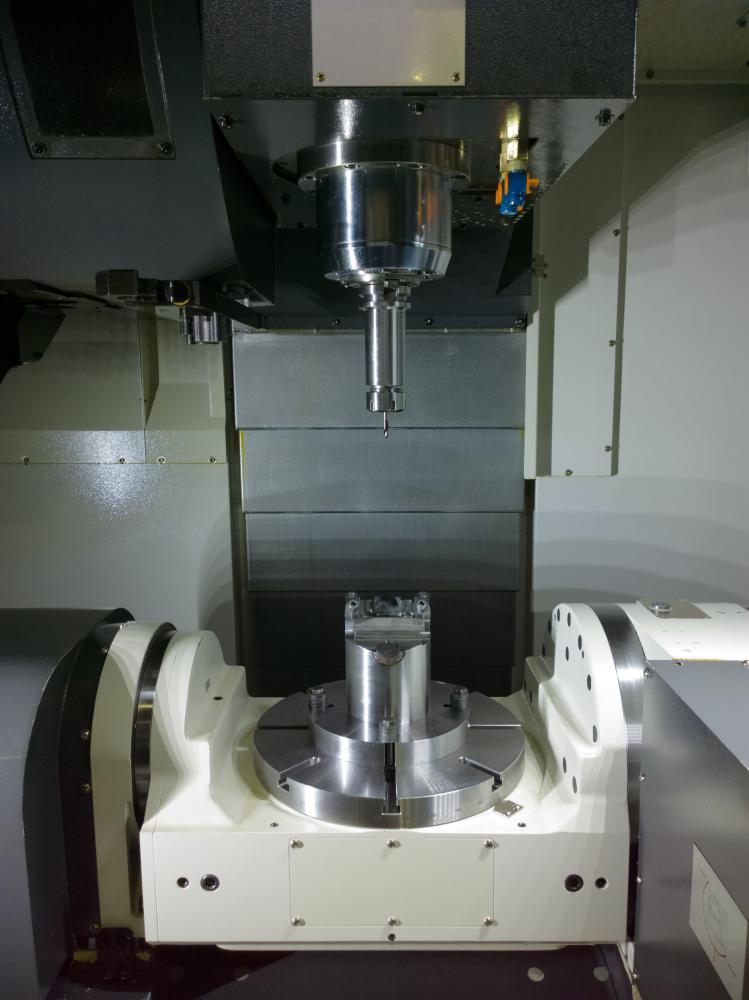

As technology evolves, so does the landscape of Special Tooling. With the advent of 3D printing and advanced CNC machinery, the possibilities have expanded exponentially. These advancements allow us to sculpt tools from the most advanced materials, maintain tolerances that were once deemed unachievable, and shorten the lead times drastically.

Each new technology we adopt at Stanek Tool & Die Inc. opens a window to previously unexplored territory in manufacturing. My hands have felt the smooth contours of a freshly CNC-machined part — a part that defies traditional manufacturing constraints and speaks volumes of modern engineering excellence.

Embracing cutting-edge technology is not a task we take lightly. It’s a continuous commitment to stay ahead of the curve and offer our clients the best of modern tooling solutions.

The Human Touch in Precision Tooling

Amidst all the talk of technology and machines, the human element remains irreplaceable. The expertise of a seasoned craftsman turning the handle of a lathe or the discerning eyes of a quality inspector — these human touches bring soul to the otherwise cold metal of Special Tooling.

Our people are the true artisans of the manufacturing era, their years of experience manifesting in every tool they create. There’s a certain magic to witnessing a skilled professional bringing a client’s idea into physical existence. It’s this intimate connection with the craft that turns a project into a masterpiece.

Meeting Client Expectations

In the business of Special Tooling, client expectations are our commandments. A part that doesn’t meet the exact requirements is of no value to a client who relies on extreme precision. Our promise to deliver is not based merely on contractual obligations but on a shared enthusiasm for seeing our clients achieve their goals.

It’s a collaborative dance where feedback loops and open communication channels are the steps we follow rigidly. Only by truly understanding our client’s needs can we aim to exceed their expectations with each deliverable.

Challenges and Solutions in Special Tooling

Every project presents its own set of challenges, from the complexities of the design to the demands of material properties. It’s a puzzle that requires methodical thinking and sometimes, outside-the-box solutions. I recall one instance where a client required a tool that could withstand extreme temperatures without compromising precision. The solution involved a blend of unique alloys and innovative cooling systems — a solution that was both effective and elegant.

Another common hurdle is the balance between durability and cost-effectiveness. Developing Special Tooling that can endure the rigors of production without becoming economically unfeasible is a delicate balancing act we perform daily.

It’s through overcoming these challenges that we not only provide value to our clients but also contribute to pushing the boundaries of what Special Tooling can achieve.

Nurturing Innovation in Tool and Die

At the core of Stanek Tool & Die Inc., the spirit of innovation is what drives us forward. Experimenting with new materials, testing unconventional methods, and constantly refining our techniques are part of our daily work. This relentless pursuit of innovation ensures that Special Tooling is not just a service we provide; it’s a promise of progress.

From our humble beginnings to our current position at the forefront of the tool and die industry, our passion for innovation has been unwavering. We don’t just follow industry trends; we aspire to set them. It’s a commitment to our craft that has cemented our reputation as leaders in the field.

In my years here, I’ve seen tools that were once considered avant-garde become the new norm. It’s a thrilling journey, one that treads the fine line between the possible and the can-be-made-possible.

With each Special Tooling project we undertake, we’re not just filling an order; we’re crafting the tools of tomorrow, equipping our clients with the means to turn their ambitious visions into tangible reality.

Why Choose Stanek Tool & Die Inc. for Your Special Tooling Needs

Choosing a partner for Special Tooling is not just about finding someone who can cut metal to shape. It’s about finding a team that understands your vision and has the capability to bring it to life. At Stanek Tool & Die Inc., we combine our deep industry knowledge with an unwavering dedication to quality and precision. We are committed to not just meeting, but exceeding the unique needs of our diverse clientele.

We recognize the trust placed in us with each project, and we honor that trust by delivering nothing short of excellence. Our craft is more than a business; it’s a legacy of craftsmanship that stands testimony to the ingenuity and dedication of our team.

When you come to us with a challenge, we see an opportunity to showcase our expertise. We invite you to discover the Stanek Tool & Die Inc. difference — where Special Tooling is not just a process, but a partnership for success.

Reach out to us today, and let’s discuss how we can assist with your tooling needs. Together, we can create the precision tools that will propel your business into the future.

What is the definition of special tooling?

At Stanek Tool & Die Inc., we view Special Tooling as the spectrum of customized tools, dies, jigs, fixtures, and molds specifically designed to meet the unique manufacturing requirements of our clients. These are not off-the-shelf items but rather precision-engineered solutions that cater to the production of components with exact specifications. This could range from a one-of-a-kind mold for an aerospace component to custom jigs that ensure the precise assembly of medical devices.

What kind of special tooling is required?

The type of Special Tooling required is a function of the project’s specifics – the industry, application, and the unique challenges it presents. For example, in the automotive sector, we might craft dies for stamping out car parts with complex geometries, or in the medical field, we might develop molds for plastic components that must meet stringent health and safety standards. Each piece of tooling is a direct response to a production need, ensuring the manufacturing process is efficient, precise, and replicable.

What is the legal definition of tooling?

Legally, the term ‘tooling’ encompasses the specialized machinery and apparatus used in the manufacturing process for producing goods. In contracts and agreements, ‘tooling’ often refers to the customer-owned assets that are designed and constructed by a manufacturer like Stanek Tool & Die Inc. These assets are produced for exclusive use in the customer’s manufacturing process, and their ownership, maintenance, and use can be significant elements in contractual negotiations.

Is specialized tooling a direct cost?

Indeed, specialized tooling is typically considered a direct cost in manufacturing. This is because it directly correlates to the production of specific goods or services. When we custom-design a tool for a client at Stanek Tool & Die Inc., that tool is an integral part of the client’s production line, and its cost is directly attributed to the manufacturing of that particular product. As such, it’s factored into the cost calculations of the produced item, influencing the overall budget and pricing.

How have technological advancements impacted the development of special tooling?

Technological advancements have revolutionized the world of Special Tooling. At Stanek Tool & Die Inc., we’ve embraced developments such as 3D printing and advanced CNC machining, which have allowed us to create tools with complex designs and intricate details that were once impossible. These technologies have also helped us in reducing lead times and enhancing the precision of our tooling. For instance, the use of high-speed CNC machines enables us to work with exotic metals and maintain tolerances that are critical for industries like aerospace where every micron counts.

Special Tooling Resources

-

National Institute of Standards and Technology (NIST): Offers a wealth of information on precision engineering and advanced manufacturing processes, including tooling and CNC technology. Visit NIST Precision Engineering.

-

Society of Manufacturing Engineers (SME): A leading source for knowledge on manufacturing engineering and technology that includes resources on tool and die practices. Visit SME Technologies.

-

American Society of Mechanical Engineers (ASME): Provides resources and information on industrial tools and manufacturing standards. Visit ASME Topics & Resources.

-

Advanced Manufacturing National Program Office (AMNPO): Hosted by NIST, AMNPO coordinates and enhances technology collaboration in the manufacturing sector. Visit Manufacturing USA.

-

International Journal of Advanced Manufacturing Technology: A scholarly resource that publishes articles on the latest developments in manufacturing technologies (access through an institute with the necessary credentials). Visit the International Journal of Advanced Manufacturing Technology.

-

The Association For Manufacturing Technology (AMT): Offers industry research, education, and networking opportunities for the manufacturing technology community. Visit AMT.

-

The National Tooling and Machining Association (NTMA): A trade association representing the precision custom manufacturing industry. Visit NTMA.

-

O*NET Online – Machinists: A comprehensive database providing detailed occupational information and skills required for machinists, including tooling specialists. Visit O*NET Online – Machinists.